Diesel engine manufacturers are using technology to reduce pollution

Aharbinger of shifts in propulsion engine know-how for the workboat market passed off in Could, nearly a 12 months in the past. That’s when a pair of MAN 1,019-hp D2862 LE428 12-cylinder diesels that had been modified to run on a dual-fuel mixture of hydrogen and diesel went into the 82’×24’×6′ Hydrocat 48, a crew switch vessel operated by Vestes, a Danish offshore wind firm.

“It’s a really cool form of benchmark mission that may be a take a look at for brand spanking new know-how to avoid wasting lots of carbon emissions,” stated Jason Blume, MAN Engines & Parts gross sales supervisor in Pompano Seashore, Fla. What appears a bit counterintuitive is the dual-fuel operation makes use of a standard MAN V12 marine engine that doesn’t should be optimized for hydrogen. It solely requires the hydrogen injection system developed by the Belgian engineering agency CMB.TECH.

Within the dual-fuel hydrogen-diesel mode, a measured quantity of hydrogen is injected into the cost air that’s then ignited with diesel gas within the cylinder’s combustion chamber. That mixture, even when operating at full load, releases much less CO2 within the exhaust gases than when operating on straight diesel. “The candy spot” for gas consumption is between 1,700 and 1,900 rpm, stated Josie Hollingsworth, MAN’s gross sales supervisor for marine engines. At that time the engine is burning about 80% hydrogen and 20% diesel.

If the hydrogen tank runs empty or an issue develops with the hydrogen system, the engines change again to being powered solely with diesel gas and make the most of selective catalytic discount (SCR) aftertreatment methods to wash the exhaust. The 2 dual-fuel engines give the Hydrocat 48 a most pace of 37 mph, a service pace of 34.5 mph, and a bollard pull of 12.8 tons.

Blume stated there’s not a lot of a studying curve for MAN’s dual-fuel engine. The operation is “seamless, it doesn’t matter what gas it’s operating,” he stated. “It’ll robotically inject hydrogen when it may and run in dual-fuel mode, with out operator enter.” If there’s a studying curve and one which requires a sure experience, it will be for boatyards putting in a hydrogen gas storage system in a vessel. That’s as a result of the hydrogen must be in liquid kind to present it the required quantity of density. “It have to be stored fairly chilly, about minus 250 levels Celsius,” stated Hollingsworth.

The hydrogen system has a few built-in danger mitigation parts. For instance, when hydrogen leaves the storage tanks, it flows via a low-pressure system of double-walled piping. The low-pressure system “is way much less more likely to have leaks,” famous Blume, and the piping being doubled-walled, it’s extremely unlikely that each partitions could be penetrated.

Presently, the MAN dual-fuel engines aren’t offered within the U.S. The engines have solely IMO Tier III approval. Nevertheless, Hollingsworth stated certification for the U.S. market is ongoing, and she or he expects to have EPA Tier 4 certification in 2024. In the long term, based mostly on the work growing the dual-fuel engines, it’s doable that the subsequent step for MAN or one other engine producer can be a completely hydrogen-powered vessel.

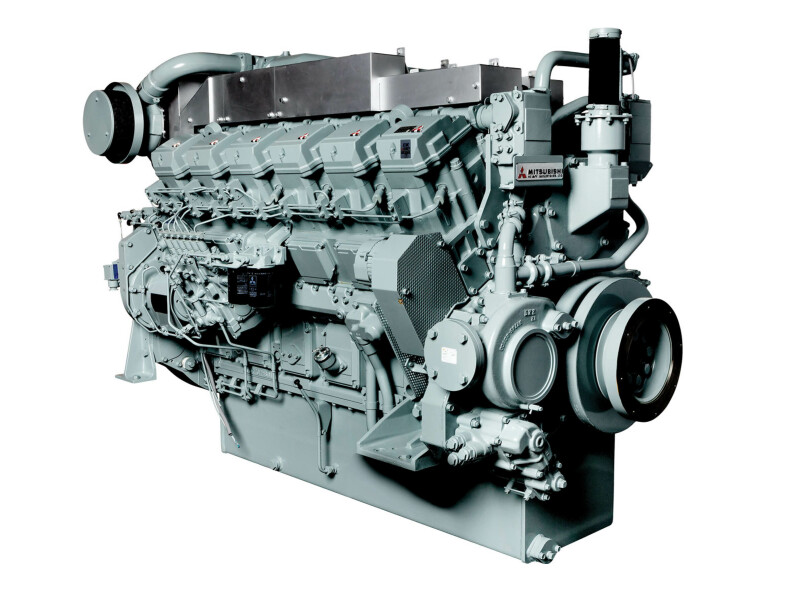

MITSUBISHI

The marketplace for Mitsubishi’s latest engine providing, the Tier 3 S12R with a 1,100-hp score at 1,800 rpm, may be very targeted. Mitsubishi’s S12R shouldn’t be designed for newbuilds. It’s designed for workboat operators taken with repowering to maneuver older vessels from Tier 1- or Tier 2-rated engines to the cleaner burning Tier 3 degree. A significant market is twin-screw, 2,000-hp inland towboats, in addition to tugboats.

The unique Mitsubishi S12R was launched some 20 years in the past with a 1,600-rpm score. The latest model, which was launched this January and has an 1,800-rpm Tier 3 score, “makes it simpler for operators to repower older vessels that have been operating at 1,800 rpm with out making gear or propeller modifications,” stated Hint Laborde, vice chairman of gross sales at Laborde Merchandise Inc., a Mitsubishi distributor, based mostly in Covington, La.

Laborde additionally famous that almost all older workboats have mechanical engines, that means gas movement is metered by an injection pump, and Mitsubishi engines are mechanical. A lot of the vessels that Laborde expects the Mitsubishi S12R to repower are already arrange for a mechanically managed diesel. “The crews are conversant in it, and so they prefer it as a result of it’s simpler and extra service pleasant” than electronically managed engines, stated Laborde. In reality, Mitsubishi Marine engines are the one Tier 3 mechanical diesel engines within the workboat market, in line with Mitsubishi.

The Mitsubishi S12R weighs in a bit heavier than a few of its competitors at 11,731 lbs. for 1,100 hp. That is perhaps a priority if the intent was to repower a high-speed or comparatively high-speed workboat, however for vessels resembling towboats and tugboats, the engine’s weight “doesn’t have an effect on gas consumption,” stated Laborde. “These are displacement-hull vessels. They don’t have to go quick, and that’s the fitting utility for a Mitsubishi engine.”

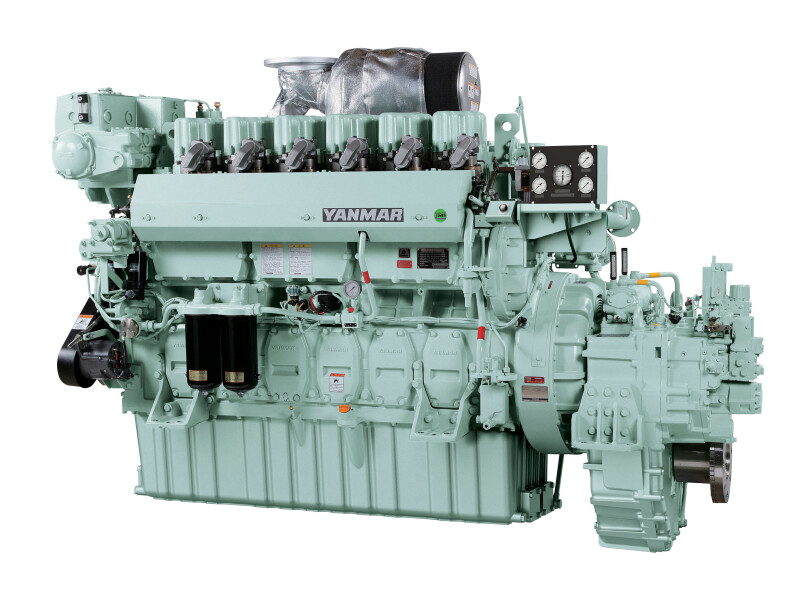

YANMAR

Workboat operators with vessels based mostly in Canada now have the choice of a brand new Yanmar engine mannequin with an SCR system that enables it to satisfy IMO Marpol Tier III emissions necessities for nitrous oxides, or NOx. It’s the 6EY17WS, an in-line six-cylinder engine based mostly on the prevailing 6EY17W engine, with a horsepower vary of 501 to 1,122. (If offered within the U.S., it must meet Tier 4 necessities, however not in Canada.) The SCR system, which is a Yanmar product designed for Yanmar engines, reduces NOx emissions by about 80% in contrast with IMO’s Tier I requirements, stated Nathan Stabler, a senior marine engineer at Yanmar America.

Yanmar’s new engine is on the market with Yanmar gearboxes with ratios from 2.5:1 to five:1. The primary Yanmar 6EY17WS goes right into a 73′ crabber as a consequence of be launched subsequent spring in New Brunswick, Canada. That’s to be adopted by a second vessel in August and a 3rd in spring 2024.